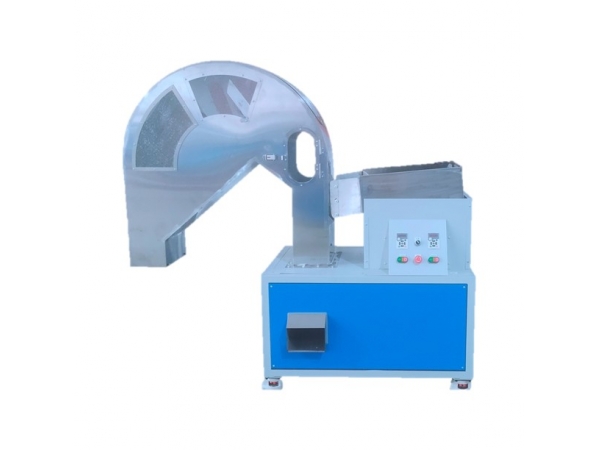

Automatic Spin Trimming Deflashing System with Air Blowing Separator

Automatic Spin Trimming Deflashing System

Product Description

.jpg)

System is composed of one set of spin trim deflashing, one set of lift conveyor, and a set of efficient of air blowing separator to separate the flashes.

Specifications

Spin trim machine

|

Specification |

||

|

Model |

PG-ST-377 |

|

|

Power Supply |

5.5KW 3ph 380V 50/60Hz |

|

|

Size |

1890*660*1320mm |

|

|

Weight |

290kg |

|

|

Gas supply |

0.4mpa-0.6mpa |

|

|

Wheel Speed |

0-6000rpm |

|

|

Process efficiency |

About 2~3kg per batch |

|

|

Batch Time |

60-90 seconds/ batch |

|

|

Flashes Separation |

Vibrating Separator or Air Blowing Separator |

|

|

Operation Mode |

Touch Screen |

|

Air Blowing Separator

|

Specifications |

|

|

Model |

PG-AB-377 |

|

Dimension |

L2060mm*W700mm*H2000mm |

|

Power Supply |

3KW 380V 50-60HZ. 3PH |

|

Machine Frame Tube |

40*40mm (Square Tube with Stoving Varnish) |

|

Sealing Plate |

1.5mm Thickness (Stoving Varnish) |

|

Vibrating Hopper Dimension |

L540*W400*H200mm (Stoving Varnish) |

|

Damping Spring |

Out Ø40mm Wire Ø 4mm L 120mm |

|

Damping Spring Holder |

Rubber Dumper Pre-Installed Screw |

|

Vibrator Motor |

0.12KW |

|

High Speed Blower |

1.1KW |

|

Blower Inverter |

1.5KW |

|

Vibrating Hopper Inverter |

0.25KW |

|

Air Running Tube |

300mm*200mm |

|

Adjustable Fuma Wheels |

4PCS(LOW NOISE) |

Features

-- Spin trim deflashing machine can spin out the thin or big flashes with high-speed centrifugal spinning force, the parts which have tear trim line will be better.

No matter regular shape parts like O-ring, gaskets, but also irregular shape parts like bumper, caps, sleeves, bushes or blocks, all can be efficiency spin deflashed by the spin trim deflashing machine.

generally the efficiency is around 2-3kg per batch, and about 60-90seconds per batch.

-- Air bowing separator use the high-speed air flow to blow out the flashes which are much lighter than the part, the product and flashes can be separated according to the different density and size by using the difference of suspension speed between main part and flashed

--Various part and flashes are available, and more efficient.

--A lifter is an good tool and connection for the user to connect from spin trim deflashing machine and the separator, to save time, labor and be more automatic. The products and flashes or burrs are lifted and transported directly to the air blowing separator to realize a on-line deflashing and burr separation process.

Photos of the Machine

.jpg)

.jpg)

.jpg)